Timeline

02/2020 - 05/2020 (3 months)

Team

Lucie Chen, Jason Hoang, Alec Li, Daisy Lu, Edward Yang

My Role

Research, task analysis, design iterations

Project Overview

This is the final project for the course IEOR 170: Industrial Design & Human Factors. Many people use a laundry basket to transport their clothes to a laundry machine or laundromat. Lugging around heavy baskets of clothes is strenuous on the human body. Once someone gets to a laundry machine, the design of most laundry baskets does nothing to alleviate strain or minimize awkward posture in the repetitive task of loading the washer with clothes. CleanCart aims to address these issues and make the process of collecting, transporting, and loading laundry more ergonomic.

Part I. Abstraction

Research Findings

- Forceful grips create a high risk for wrist and other upper limb injuries

- Lifting and carrying laundry baskets to and from the washing machines puts strain on our body; specifically, the back, shoulder, arms, and hands

- Laundry baskets grips cause a lot of strain on our hands.

- Working with wrists in a bent rather than straight position puts stress on the tendons and tendon sheaths in the hands and wrist, and increases the risk of injury, especially where the task also involves force

- Removing dirty laundry from the bottom of laundry baskets often requires the user to bend more than 90 degrees to reach the laundry

- Awkward posture can lead to the development of musculoskeletal injuries, particularly back injuries from the excessive trunk and neck flexion

white dots indicate strain positions on the body

We decided to focus on front-load washers due to more awkward postures, and we aim to address two major problems in our design: carrying laundry and removing laundry from the basket. For front load washers, moving laundry from the basket to the washer or sorting laundry requires repetitive pinch grips while picking up pieces of laundry. While loading front load washers, an awkward static position is maintained for the duration of the task.

After analyzing hierarchical relationships, information flow, location & environmental context, we addressed the need/problem: most laundry baskets today are designed for static use (temporarily storing dirty laundry), but their inadequacies are quite apparent in dynamic use. We aim to design for ergonomic gripping, lifting, and carrying, and minimize awkward posture (bending over) while loading clothes into washers.

Assumptions of the Design

- the range of feasible laundry loads that our design will accommodate should range between 10-20 pounds of laundry consisting of a volume of 3-4 cubic feet

- designed for use in home/residential settings by adults (not children or elders)

- aim to accommodate use by at least a 5% female (assumes that a design accommodating the stature and physical proportions of a smaller person will also be ergonomic for a larger person)

- design a height-adjustable handle to adjust for more than 5% IMO because the 5% female may cause problems for people in the higher percentile

Functional Requirements & Constraints of the Design

- reduce the repetitive motion of grabbing laundry from the basket to the machine, which also means a user spends less time in a bent position

- reduce the weight load carried to under 22.4lbs (assuming 20lbs of laundry)

- reduce the amount of time spent in a pinch grip

- durable materials and construction to support the weight

- look minimalistic and aesthetically pleasing

- the cost to manufacture this product, which cannot be too high because the prices of most laundry baskets range from 8 - 30 dollars

- should be collapsible or small enough to store easily in an average closet

Part II. Conceptualization

Brainstorming Process

Existing Product

Whitmor Round Commercial Removable Liner and Heavy Duty Wheels-Chrome Laundry Hamper (Amazon’s Choice Hamper on Wheels)

What works:

- Wheels to reduce weight load carried

- Dimensions (23.6 W x 32.0 H in.) fit into an average closet

- Large capacity (3-4 washer loads)

- Removable bag for easy cleaning

- Durable

- Aesthetically pleasing

What doesn’t work:

- Expensive ($60)

- Doesn’t address awkward postures & repetitive motions when loading laundry into the machine

- Only works on flat terrain

- No handle

Concept Sketch & Iterations

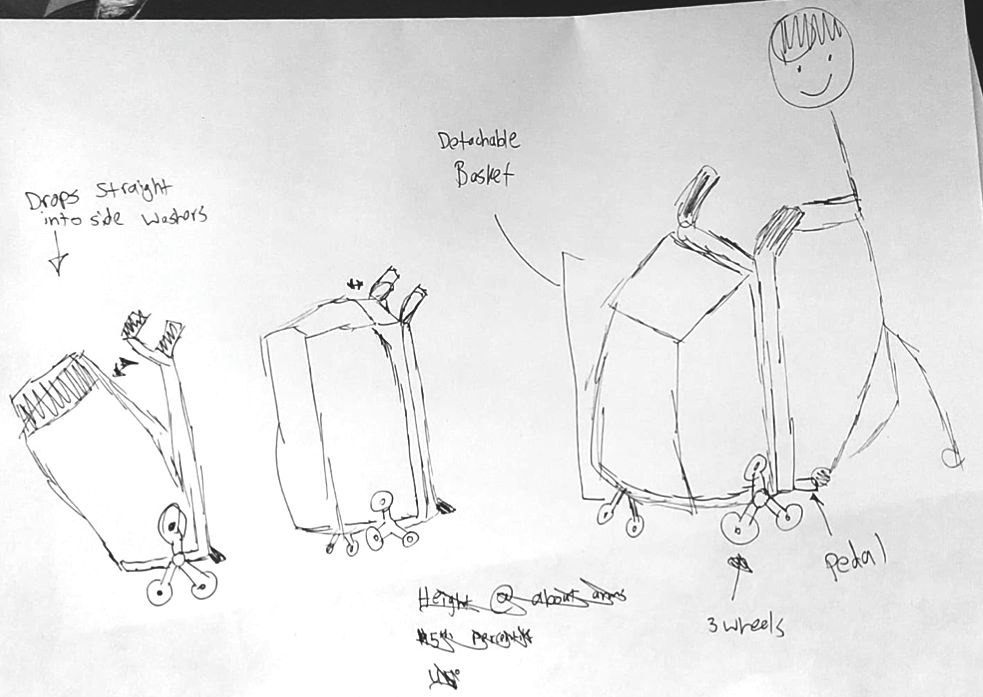

Concept 1

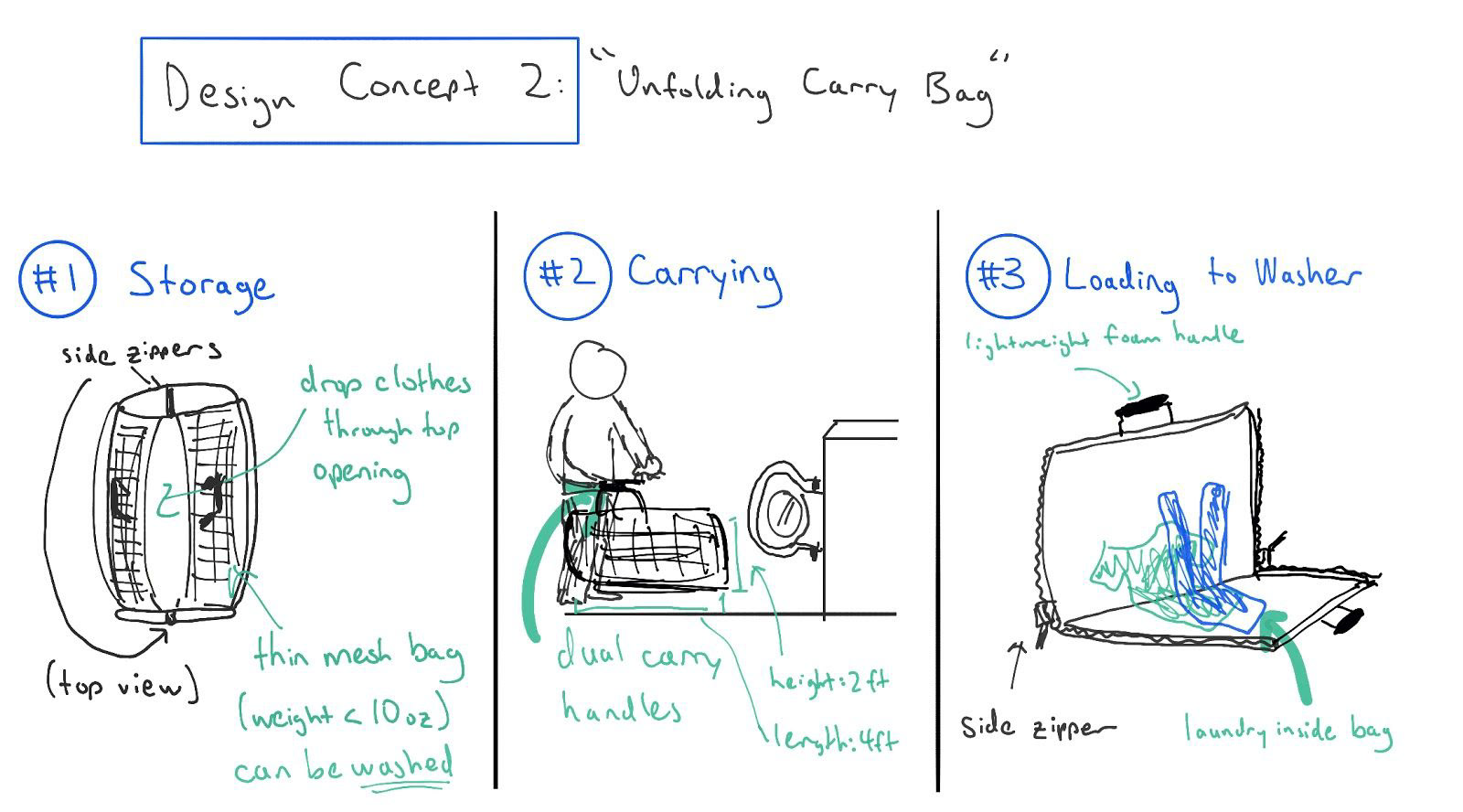

Concept 2

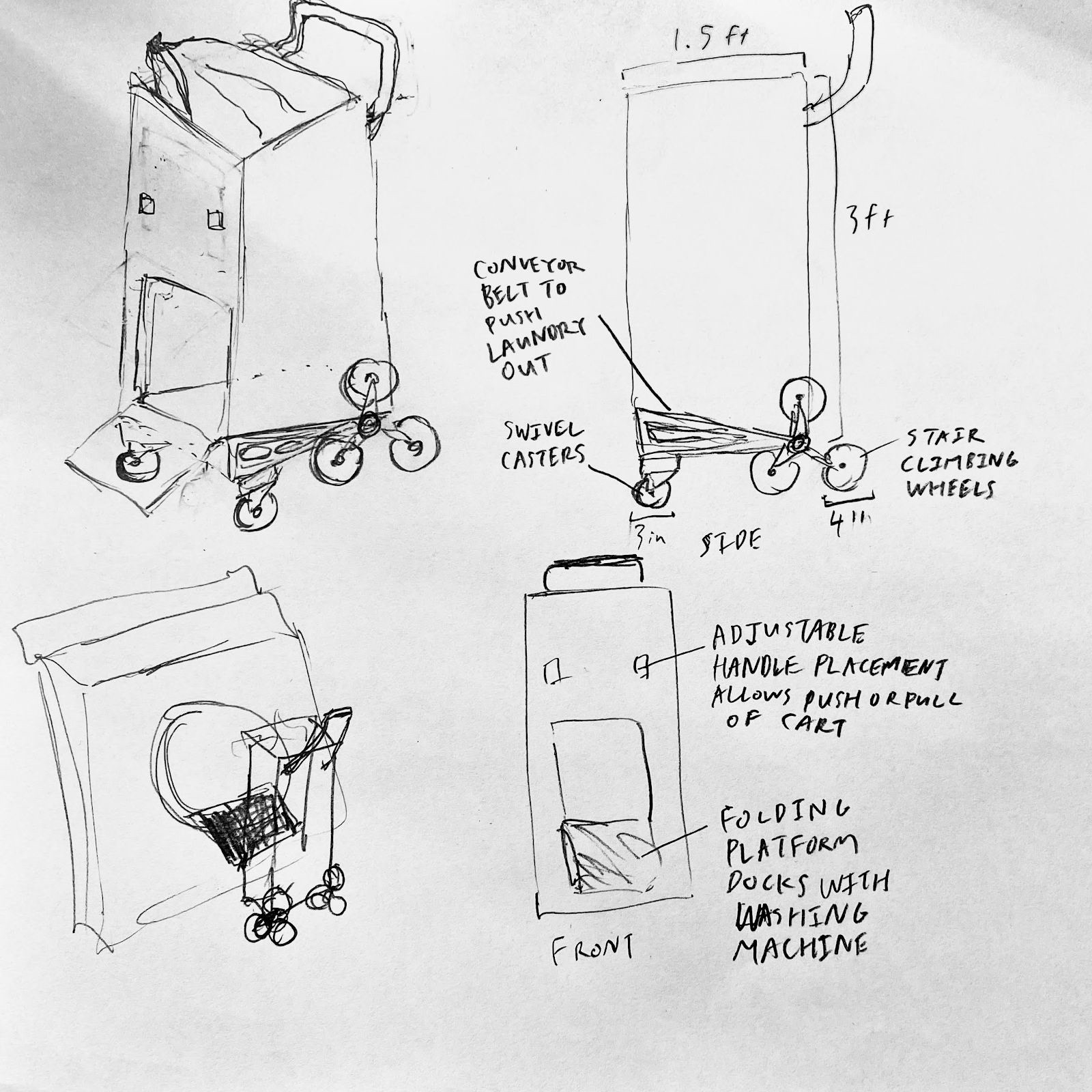

Concept 3

Iterative Approach

- works well for front-loaded washing machines

- seeking to optimize both functionality and convenience

- the ability to collapse for storage (still in the process of being considered)

- implementing adjustable handles (increase and decrease the height at which the pressure is applied, allowing for a wider range of users to be at a safe posture)

Design Selection Criteria

- whether the design reduces the weight load carried (Concept 1 & 3 both utilize wheels to dramatically reduce the force required to move laundry. Concept 2 did not address this problem)

- whether the design reduces awkward postures while moving laundry from the basket into the washer (for removing pinch grip, Concept 3 addresses this problem best since there are no awkward postures required to turn a crank. Concept 1’s detaching mechanism is hard to implement well. Concept 2 needs to push a laundry bag into a washing machine which still requires the awkward posture of bending over)

- Concept 3 is selected

Final Sketch

Part III. Realization

Price is also a critical factor. We decided to use a hand crank instead of a button to operate the conveyor belt on concept 3, which also has the benefit of not needing a power source, and no electrical malfunctions (especially from the wet laundry).

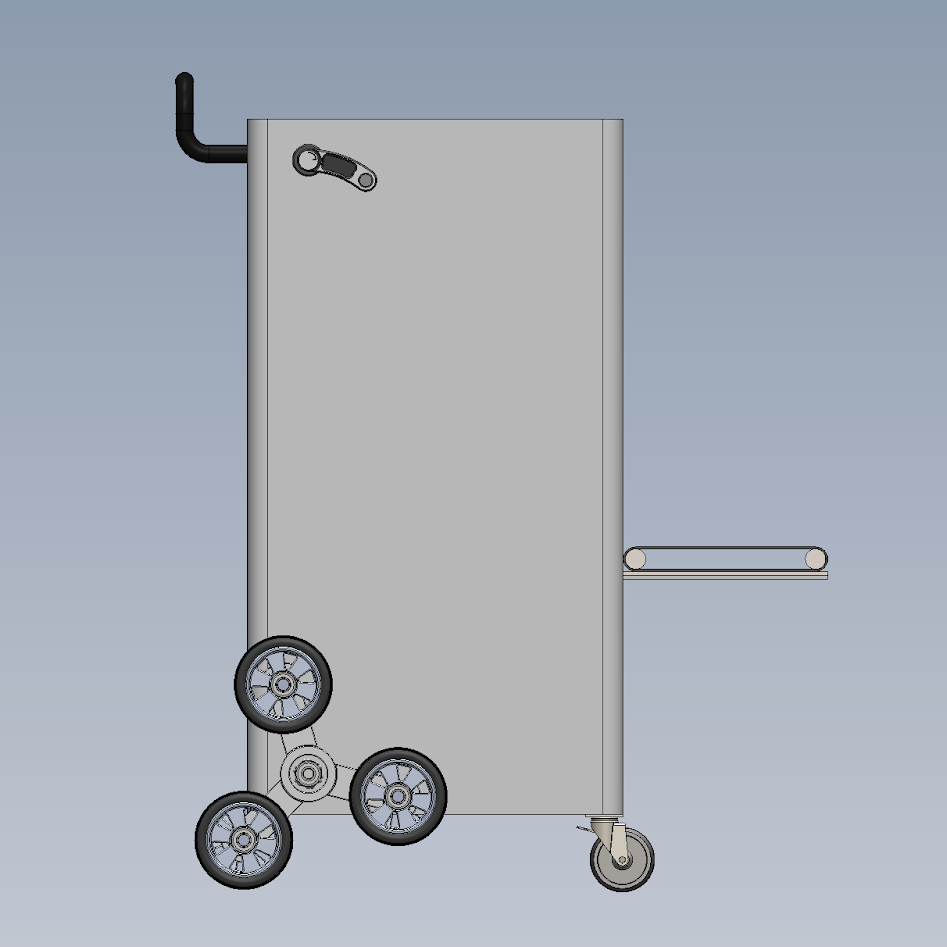

Final Design (CAD Model)

Features

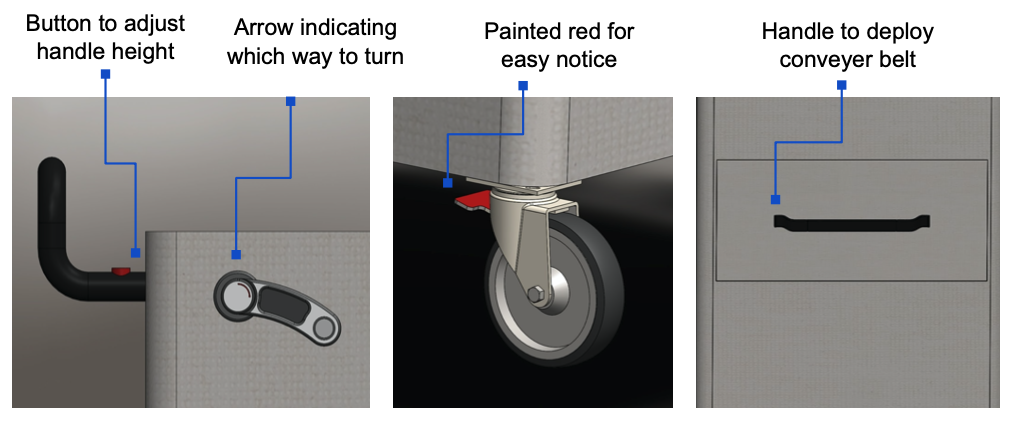

- adjustable handles

- stair climber wheels & swivel casters

- a deployable hand crank “conveyor belt” mechanism

Instructions

- Load laundry via the top of the basket. Once the desired amount is loaded proceed to step 2

- Adjust the handlebar so your arms and elbow are at 90 degrees.

- Check to see that swivel casters are unlocked

- Roll the cart to the washing machine

- Lock the swivel casters so the laundry basket does not move

- Unhinge flap and dock with side-loading washing machine

- Crank the hand-crank on the top to load clothes

cross-sectional view

side view

detailed description

Evaluation Approach & Next Steps

We would want to ask how much the users felt like our design improved upon their status quo process in a number of key areas of the laundry loading process (e.g. storing, moving, unloading), and we would also attempt to measure the actual body postures, anthropometry, and forces required in using our design. The potential limitations of our laundry basket are that it may not be as portable or easy to store as some other soft fabric solutions, which would make it less accessible and usable in different living situations (especially in buildings with narrower hallways, rooms, and corners where wheeling around a laundry cart would be difficult and unwieldy). In our next design iteration, we would want to address making the design even simpler and easier to use by reducing the number of potentially confusing controls and signals.

Reflection

This is the first human-centered design class I took. As a team, we found it particularly challenging to find secondary research on our problem area to help substantiate the claims we were making and guide our focus into particular areas of our design that we needed to prioritize. But I think it was rewarding to go through the iterative approach of improving various components and refining the details of our design as we came up with new creative ideas to make our design effective. I learned a lot throughout the course as well as the project, such as using Kinovea for motion capture, computing RULA score for risk estimation and analysis, and calculating Bloswick shoulder moment and estimated compressive force. I also learned about human ergonomics & the understanding of anthropometry, physiology, and musculoskeletal disorders. Additionally, I gained some practice in designing controls, signals & displays, writing error-proof instructions, and designing 3D prototypes in CAD software.